1. Sanar da aika rashin wutar lantarki, kuma ma'aikacin lantarki zai kula da hanyoyin gazawar wutar lantarki;

2. Tabbatar da cewa an katse wutar lantarki na crusher, da kuma sanya alamar tabbatarwa na akwatin aiki da kuma rataya katin kulawa daidai;

3, da lubrication famfo matsa lamba taimako magani;

4. Jawo maɓalli na igiya don bel na ma'adinan kuma tsaftace kullun a kan bel;

5. Cire manyan guda huɗu, kamar murfin fitarwa na ɗagawa, kasko, farantin murfin da kafaffen murfin ƙurar mazugi. Yayin aikin hawan, ma'aikata na musamman za su ba da umarnin crane kuma su bi ka'idodin aikin hawan;

6, tsaga farantin: tsaftace slag a kan kusoshi na farantin, cire kulle kulle, cire farantin don duba ko zai iya ci gaba da amfani, idan yana bukatar musanya, nan da nan sami sabon farantin.Lokacin amfani da guduma da kuma guduma mai sulke, hannun da ke rike da guduma ba zai sanya safar hannu da sanya tabarau ba, kuma akwai ma’aikatan sa ido;

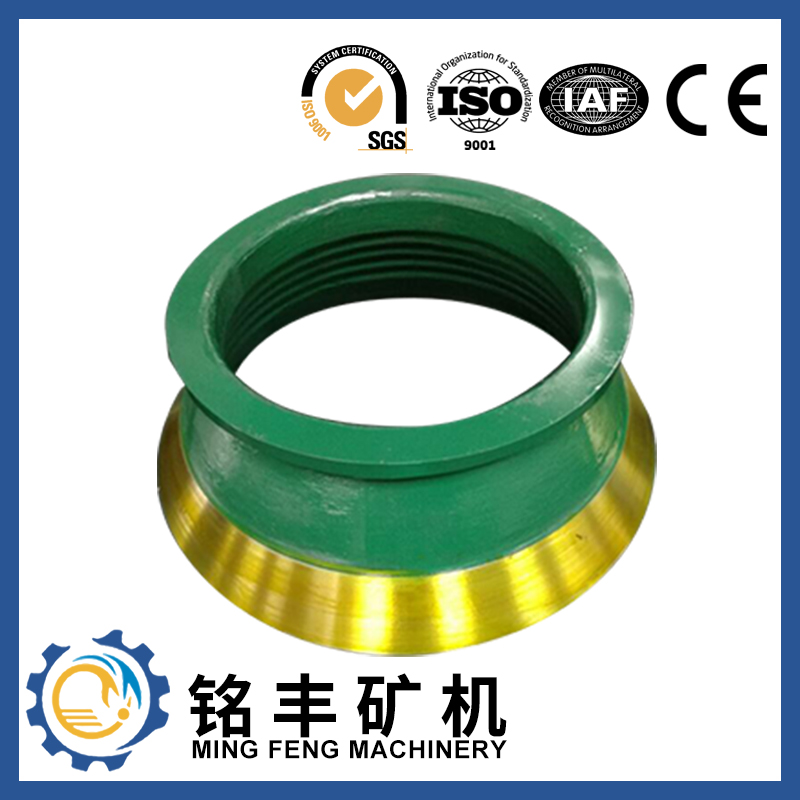

7, cire ƙayyadadden mazugi: duba girman nau'in zobe (dabaran) occlusion, fara motar hydraulic don jujjuya zoben zobe.Wannan tsari dole ne a kula da shi ta wani mutum na musamman. Lokacin da mazugi da za a ƙayyade ya fito gaba ɗaya, zai kasance. a ɗaga shi zuwa matsayin da aka keɓe;

8, dismantling da dagawa mazugi: da tsari ya kamata a gudanar da wani musamman mutum, da dagawa tsari ya kamata a hankali da kuma tsayayye, domin ya hana lalacewa ga mazugi mazugi hali;

9, duba ma'aunin nauyi, farantin tushe, daji mai ɗaukar nauyi, shingen kwance (farantin) da sassa masu alaƙa;

10, dagawa da sabon mazugi: ya kamata ya dace da buƙatun na ƙazantattun zobba da igiya igiya, a hankali shafa stains na motsi mazugi axis tushen, dagawa ya kamata rage gudu a lokacin da ya sa a kan eccentric shaft, da ƙwararrun ma'aikacin jinya umurnin, motsi mazugi da kuma. an haɗa shingen eccentric kuma ya kamata ya daina faɗuwa lokacin da bai cika wurin ba, wannan lokacin yakamata a haɗa tsarin buɗe famfo mai lubrication 1 ~ 2 mintuna, sannan faɗuwar mazugi mai motsi a wurin;

11. Dauke sabon mazugi mai tsayi: tsarin sanyawa dole ne a jinkirta shi a hankali, bincika a hankali ko madaidaicin mazugi da ramin gear sun dace daidai, kuma ko farkon madaidaicin zaren mazugi ya dace da wurin farawa na matrix. zaren.Idan abubuwan da ke sama sun kasance daidai, fara motar hydraulic kuma juya madaidaicin mazugi zuwa tashar fitarwa don saduwa da bukatun samarwa.Wannan tsari kuma yana buƙatar kulawa ta musamman, duba girman girman darajar kayan aiki;

12, shigar da farantin ciyarwa: farantin ciyarwa mai daidaita fil ɗin a cikin mazugi mai motsi na kulle mata a ciki, kulle kulle, yin amfani da bayanan sledgehammer tare da labarin 6;

.

14. Hoisting kafaffen mazugi kura murfi, murfi farantin, babban tukunya, ciyar da bakin kariyar murfin da sauran hudu manyan guda hudu. Bayanan tsari iri daya ne da labarin 5;

15. Mayar da bawul ɗin matsa lamba na famfo mai lubrication kuma duba ko matsa lamba ya dace da bukatun samarwa;

16. Sake saita igiya mai jan bel, cire katin overhaul, canza akwatin aiki zuwa matsayi na atomatik, kuma tsaftace shafin tare da kayan aiki;

17. Bayan an magance abubuwan da ke sama, sanar da mai aikawa don kunna wutan lantarki.

Lokacin aikawa: Janairu-11-2022